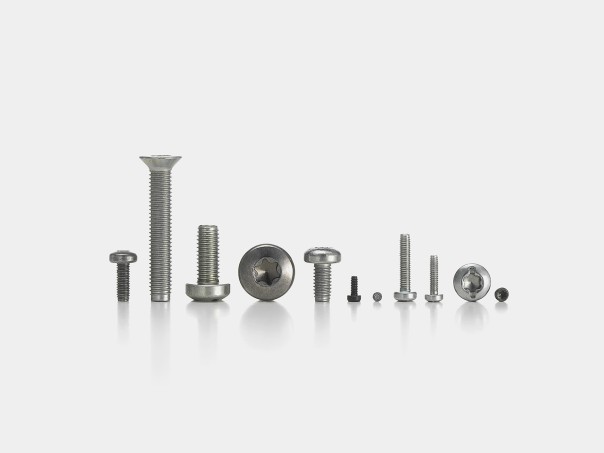

TAPTITE 2000®

This fastener allows non-cutting thread forming during the insertion process. The product features low insertion torques and high preload forces. Tapered thread tips make it easier to locate the screw. The thread flanks have a radius profile which ensures constant friction conditions and contact pressures to minimise deformation of the mating material. This reduces insertion torque significantly, resulting in maximum preload force with low scattering.

- TRILOBULAR® thread cross-section

- Reduced costs due to simplified process

- Secure and reliable screw connection