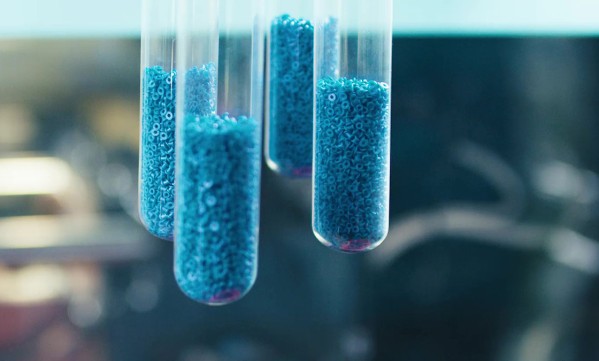

Broad selection of materials

Fundamentally, all plastic malleable, metallic materials that fall under the term wrought alloys are suited to cold massive forming: low and high-alloyed steels, aluminium, titanium and non-ferrous metals.

The selection of a material for a cold formed part is dependent upon the technical specifications and the material properties of the finished component.