Transformation

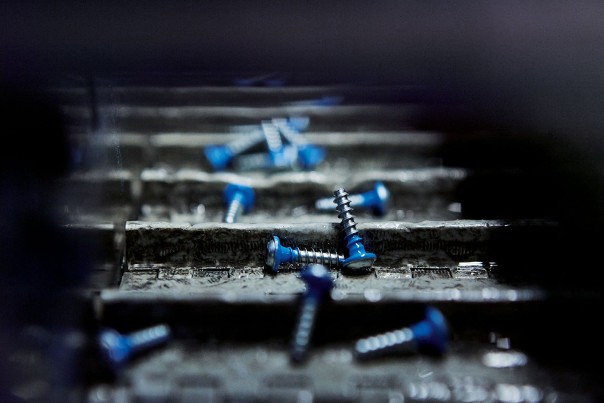

With transforming processes such as rollers, castors, furrows or knurling, threads or knurls are applied to the slug. As a positive side effect, the capacity of the parts is also improved by this.

With transforming processes such as rollers, castors, furrows or knurling, threads or knurls are applied to the slug. As a positive side effect, the capacity of the parts is also improved by this.

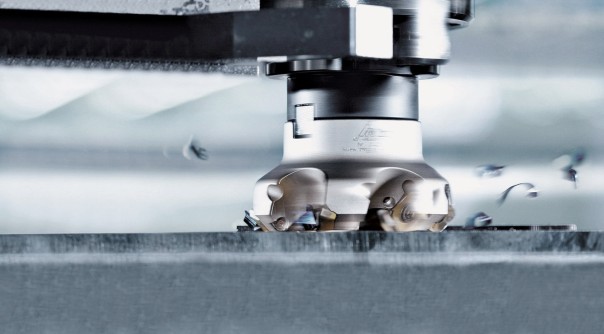

Thanks to cutting post-processing such as turning, milling, drilling, rubbing, grinding or reaming, precise contours can be created, holes are attached or internal threads cut.

With heat treatment methods such as annealing, hardening or quenching and tempering, the mechanical properties of a component can be specifically influenced – for example, strength, toughness or ductility.

Thanks to various methods or surface technology – for example, passivating, tinning, burnishing or varnishing – components are protected against corrosion, changed in their friction coefficient or receive unique aesthetic surfaces.

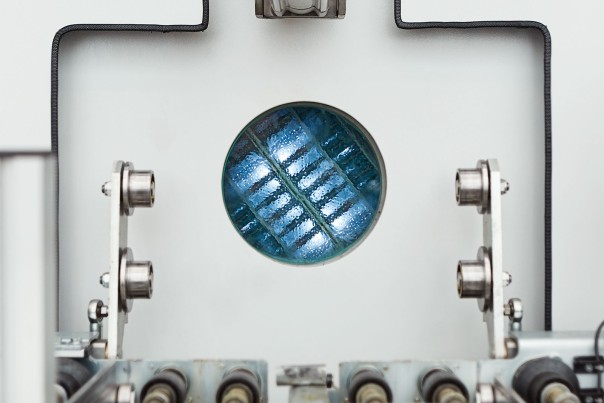

Test procedures, such as image processing systems using shaft or head camera, eddy current or structure testing as well as roller devices, allow degrees of purity from 0 to 3 ppm, depending on the component.

With state-of-the-art, multi-layer cleaning processes such as immersion cleaning, ultra-sound or pressure-flooding, various impurities can be safely and comprehensively eliminated.

Thanks to various techniques, processes and materials, chemical or mechanical fuses as well as sealing and insulating, functions can be integrated into components.

With our fitting service we fulfil the desire of our customer for pre-finished assemblies. We hereby not only mount the parts produced by us, but also, if necessary, purchased parts from certified suppliers.